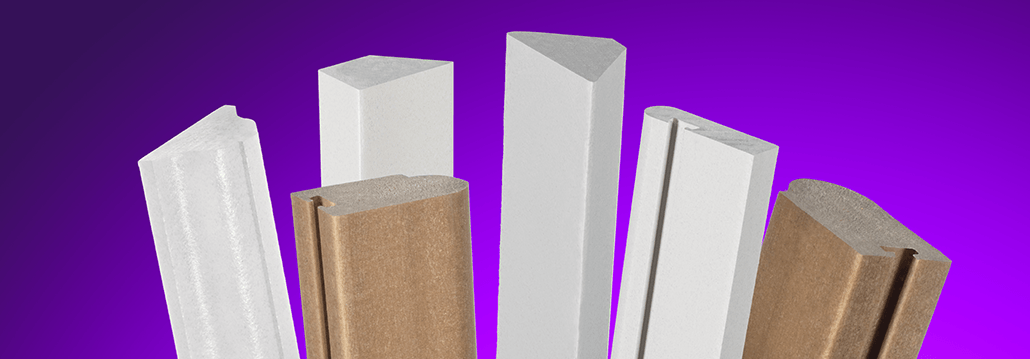

Our new Wood Polymer Composites brochure provides more information than ever before, allowing you to make an even more informed choice when it comes to the specification of WPC for extruding your profiles.

Wood Polymer Composites (WPC) combine polymers with wood fibres creating a material that combines the inherent properties of timber with the following additional performance characteristics:

- Consistency- As an engineered solution WPC profiles have even density through the length and cross section of the profile, eliminating internal voids and weak spots.

- Stability- WPC is self-skinning, forming a smooth surface improving the weathering of the profile, reducing bowing, cracking or warping.

- Reduced Water Absorption- WPC is not as susceptible to changing moisture levels in the environment, reducing the possibility of the material splinting and splitting.

- Improved Weathering- UV stable. When exposed to accelerated weathering conditions, in accordance with EN 607, WPC demonstrated outstanding performance.

- Less susceptible to rot- The reduced moisture retention in the WPC contributes to the product being less likely to suffer from rotting.

- RAL colour options– WPC can be extruded in a range of RAL colours

- Onsite alterations– WPC can be screwed, nailed, glued and pinned and additional alternations can be made using standard joinery tools.

These performance characteristics and the associated lower maintenance costs are seeing WPC being used in applications that were traditionally timber based.

WPC Technical Overview

WPC is an engineered solution incorporating extenders to improve and maintain profile stability and material density. The natural wood fibres are chemically bound within the formulation to enhance durability making it an ideal material for internal and external applications.

All Reddiplex profiles are manufactured under a factory controlled conditions to predetermined specifications increasing overall quality consistency.