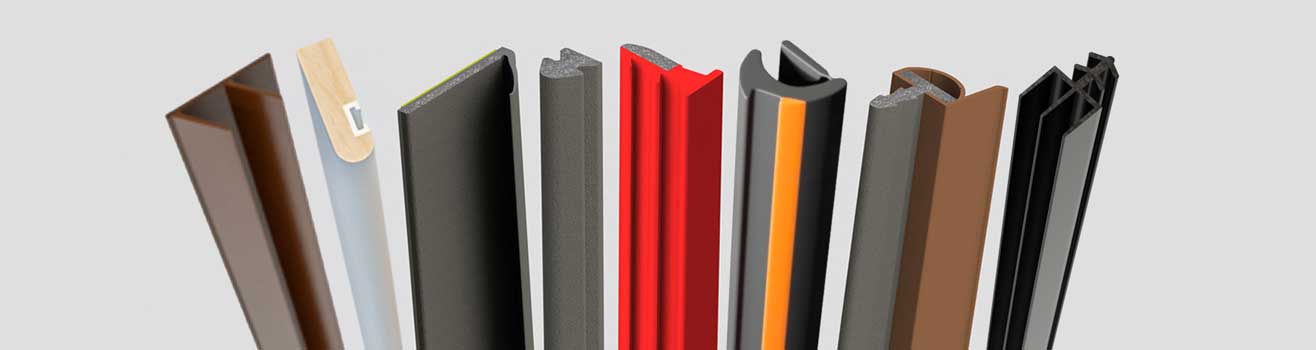

Plastic and Rubber Extrusion

Along with our customer service, our knowledge of material behaviour, onsite tooling, and technical processing positions us as a global leader in the extrusion of plastic and rubber profiles.

Material Knowledge

We are continually developing our material knowledge to ensure customers receive the most up-to-date guidance on material selection. This approach means we have developed expertise in extruding materials ranging from TPE, PVC, EPDM and WPC’s through to specialist engineering polymers such as Polycarbonate, SEBS and PEEK.

Manufacturing Capabilities

The manufacturing capabilities we have onsite allow us to offer single, co-extrusion and triplex extrusion incorporating a variety of curing techniques. These range from water bath and air cooling through to the vulcanisation of rubber using microwaves and our specialised bed of glass ballotini beads. Perfect for curing low density profiles.

We understand that detail is where you add real value; therefore we have an impressive portfolio of inline capabilities and secondary operations. These functions include colour matching, embossing, tape application and printing. We also provide specialist packaging options to ensure your profiles are delivered in the best condition for further processing or retailing.

Confidentiality

We are privileged to work with customers on innovative designs for new systems and always respect the need for confidentiality. We have extensive onsite technical facilities allowing tooling to be designed, controlled and manufactured maintaining customer confidentiality at all times.